Unlike larger manufacturers, the small manufacturer is more agile recognizing and adjusting to situations in real-time. This reality, perhaps ironically, has exploded with COVID-19. All of a sudden supply chains from China were cut off. Small manufacturers quickly became the alternative suppliers. With real-time visibility, small manufacturers have the same awareness of suppliers as the big manufacturers. Even as the country navigates the painful process of re-opening, small manufacturers are uniquely positioned to answer the call. Tier 2 and 3 manufacturing suppliers have new importance which makes them extremely attractive to buyers.

Complex Supply Chains Turn to Small Manufacturers

Supply chains are inherently complex with many touches and a variety of different organizations. The challenges are influenced by delivery capacity which persists during COVID-19, despite shrinking margins. When small manufacturers think about the supply chain it often comes down to how to leverage automation and software technology to increase the capacity and scale of product and material delivery.

Ten years ago, there was an aggressive move to a global supply chain which has made matters far worse during the COVID-19 pandemic. More than a decade ago numerous analysts believed that reducing supply chain complexity was essential for success in the future. The future is here.

Complexity is like a cancer that destroys supply chain efficiency. Things that increase supply chain complexity include global sourcing, new SKUs, natural and manmade disasters, compliance requirements, transportation availability, rising commodity prices, consumer preferences, and COVID-19.

Resolving supply chain complexity with flex manufacturing and edge computing

There is great excitement about flex manufacturing and the use of edge computing. There are so many advantages to making complex machines truly smart. Many machine builders preparing to sell their company, have discovered how smart machines can also be adaptable, more serviceable, and easier to operate. This is a dramatic and important development as USA-based small manufacturers must measure the risks and costs of managing everything, particularly in the post-COVID world.

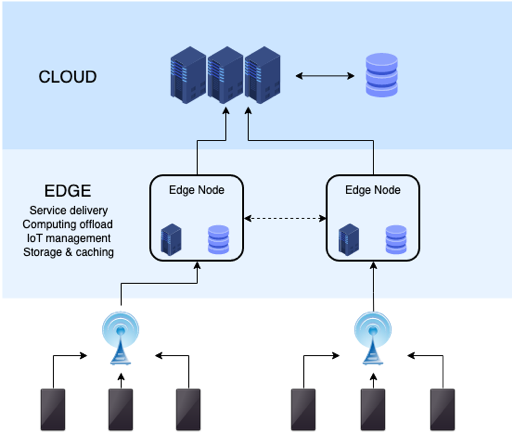

Edge computing is a distributed computing paradigm that brings computation and data storage closer to the location where it is needed, improving response times, and saving bandwidth. Modern edge computing significantly extends this approach through virtualization technology that makes it easier to deploy and run a wider range of applications on the edge servers.

Reshoring improves outlook for USA small manufacturers

Anna Shedletsky, a senior contributor for Forbes, shared that widespread globalization means nearly every supply chain is impacted by COVID-19. Tariffs made supply chains longer as companies worked to “add transformations” outside of China to avoid added costs. Now those same manufacturers are exposed to a large surface area: as various regions open and close, potentially multiple times over the next 24 months, manufacturers are going to be playing whack-a-mole with component shortages. Smaller companies and specialized products are the most vulnerable: they often rely on single-sourced components.

Small USA-based manufacturers are taking an important role during COVID-19 and beyond; they are the new suppliers because manufacturers need to be able to get needed parts locally sourced. With many commercial fleets grounded, freight capacity has drastically decreased, the answers are in the neighborhood and will remain so for many years to come. This makes buying and selling small manufacturing firms particularly attractive in 2020 and the rest of the decade.

“If I ever go looking for my heart’s desire again, I won’t look any further than my own back yard. Because if it isn’t there, I never really lost it to begin with.” (The Wizard of Oz)

Contact us with any questions.